Adequacy Check for Expander Inlet Separator

A Computational Fluid Dynamics (CFD) study was performed for a detailed analysis of fluid flow patterns and distributions within an Expander Inlet Separator. MySep software was used on-top to rate the design in terms of separation efficiency.

MySep analysis, coupled with insights on gas flow patterns from the CFD simulation, allows to validate the adequacy of separation performance.

BUSINESS PROBLEM

In an LNG treatment plant in Australia, modifications were required to broaden the operation window to include different gas blends.

The Expander Inlet Separator currently handling 950 MMSCFD gas and 45 m3/h HC liquid was identified as critical for achieving the required export specifications.

The client commissioned Kranji Solutions for an independent engineering verification of the vessel sizing and internals design.

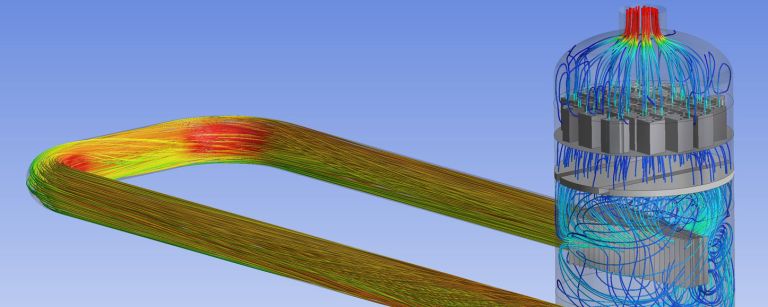

CFD ANALYSIS

Computational Fluid Dynamics indicated some flow maldistribution in the upstream piping, despite the straight portion of the inlet piping being long enough. This flow maldistribution was also reflected within the inlet separator, whereby higher gas velocities were observed on the left-hand side (seen from the inlet nozzle).

The possibility of liquid re-entrainment from the liquid surface was evaluated. The simulation results validated that liquid re-entrainment does not occur.

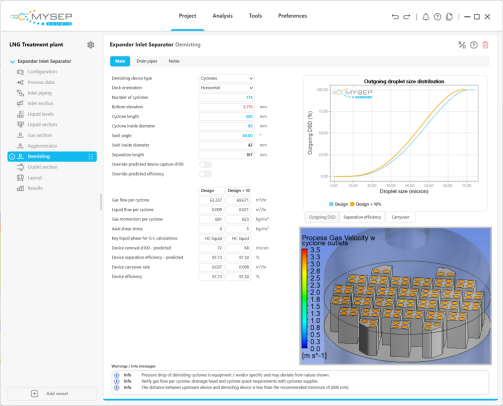

The flow distribution through the agglomerating mesh pad and the demisting cyclones was reviewed. When the distribution on these devices is even, the efficiency predictions by MySep Studio will be accurate. Thus, the magnitude of carry-over can be quantified.

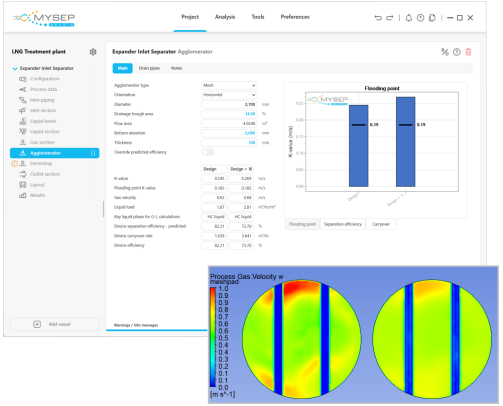

INTERNALS PERFORMANCE REVIEW

The mesh pad is operating in flooded condition, pre-conditioning the flow for the demisting device. Part of the liquids on top of the agglomerator collect in the drain troughs, and part of the liquid droplets travel to the downstream demisting device. Device efficiency per the MySep Studio predictions is 74% for the CFD case.

The demisting cyclones are reviewed both qualitatively and quantitatively. The gas flow is evenly distributed over all the demisting cyclone tubes. With this even distribution, MySep Studio can accurately predict the demisting cyclone efficiency. The predicted device efficiency is 97.3%.

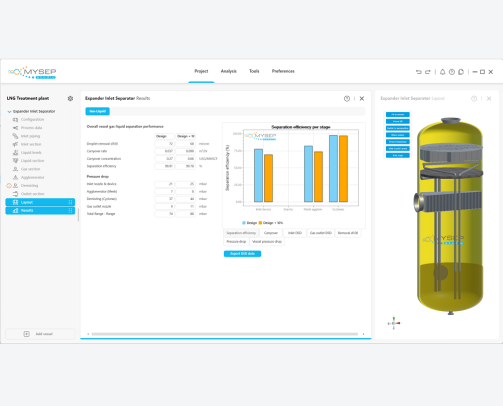

MYSEP: SEPARATION EFFICIENCY

MySep software was used to validate the design case and the CFD case (+10% margin).

MySep determined the efficiency per stage inside the Expander Inlet Separator and provided an overall liquid carryover of < 1 USG/MMSCF, which in this case is acceptable for the customer’s operation.

SUMMARY

Expert application of CFD modelling revealed rather even flow distribution within the vessel for both gas and liquids. Liquid re-entrainment from the liquid surface was evaluated and is not an issue.

Flow through each internals device was reviewed via CFD to check the adequacy of the separator design. Validating uniform flow allows for accurate efficiency predictions within MySep Studio.

The magnitude of carry-over was quantified and was found to be acceptable for this case study (< 1 USG/MMSCF).