CFD

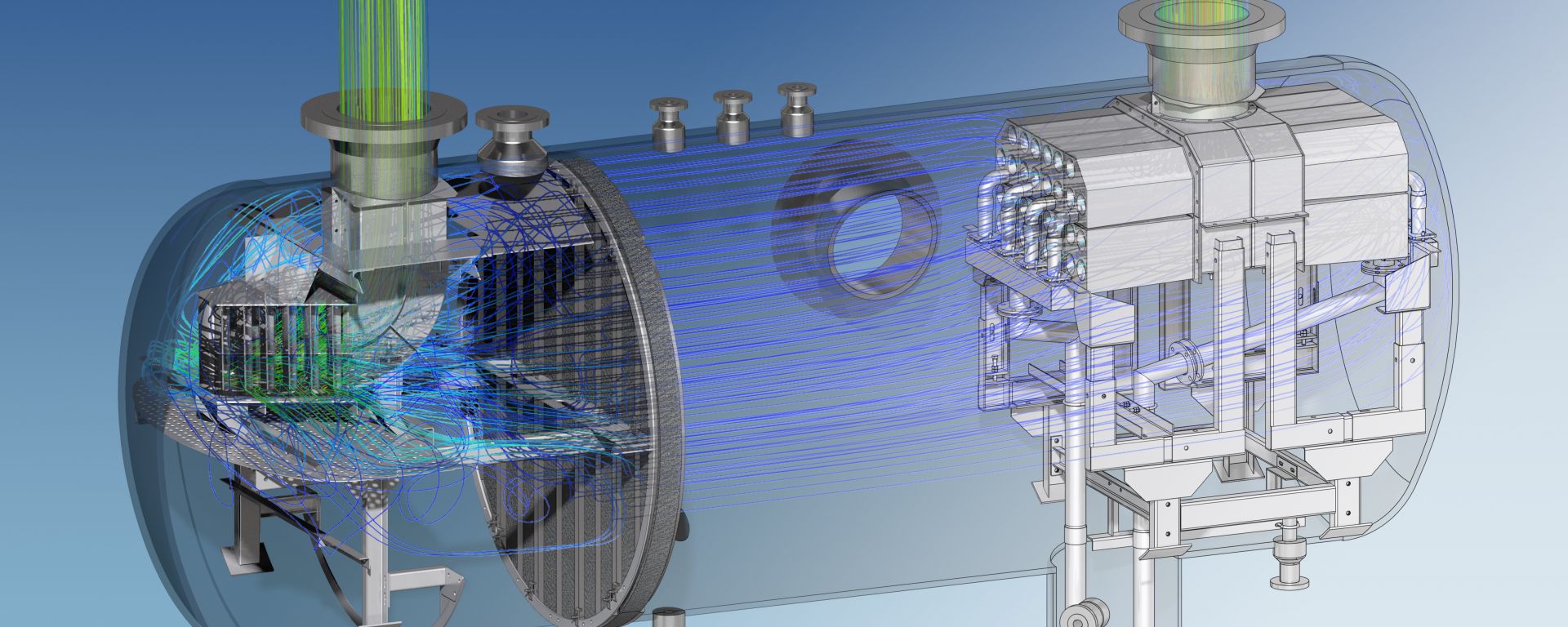

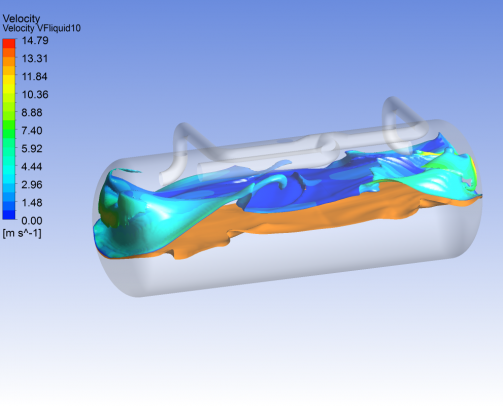

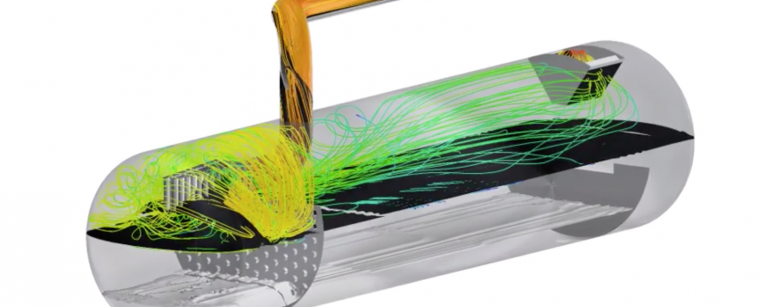

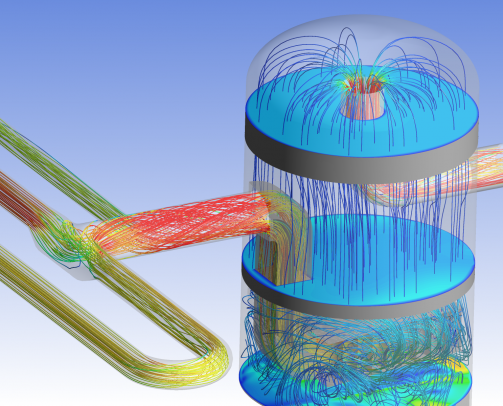

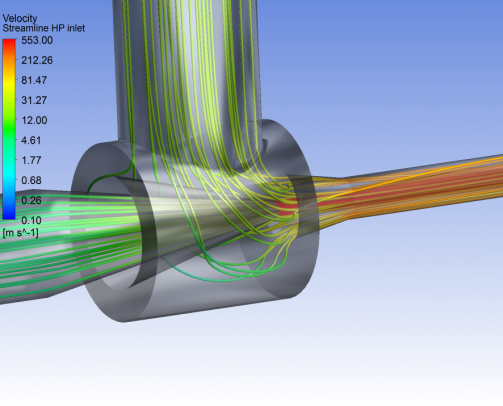

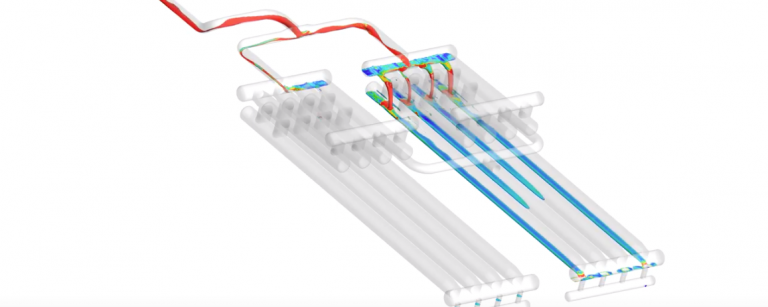

In addition to many applications outside the process industry, for upstream, midstream and downstream Oil & Gas, CFD is an invaluable tool. It offers understanding of phase-interactions and quantifying velocities, forces and phase behaviour in complex flow systems.- Kranji Solutions has over 20 years’ experience assisting service companies and leading process operators to remedy process operation failures and constraints on production. Applying our industry knowledge and modelling skills we also develop unique equipment for our customers where they have challenging production and processing requirements involving 2-, 3- and 4-phase flows.

Troubleshooting and Analysis

Using CFD in combination with MySep separator modelling software (www.mysep.com), or heat exchanger and process modelling, Kranji provides insight into the root cause of malperformance. Our specialisation in the application of CFD to internal flows, where phase-interaction is key to equipment performance, has resulted in a unique skill profile which has brought us success in assisting Oil & Gas customers world-wide.

Our main application areas include:

-

Phase-separation

-

Heat transfer

-

Multi-phase flow dynamics

-

Impact of motion on performance (FPSOs)

-

Erosion

Validation of Remedial Measures

Having identified the causes of sub-optimal performance or operational failure, Kranji has deep experience of defining practical industry remedies. This may involve developing modifications to a unique flow system or entail recommending a range of vendors supplying suitable equipment. CFD modelling provides the client with confidence that process requirements can be met with a retro-fit or new-build solution.

Design and Equipment Development

We also undertake product development of proprietary equipment for customers. Sometimes this type of contract research involves CFD coupled with experimental test and validation using our in-house laboratory facilities and extensive research experience.

Benefits of CFD

Whether the concern is malperformance of existing operations or challenging new operational requirements, Kranji Solutions expert CFD modelling services allows our clients to:

-

Diagnose the root cause of mal performance or equipment failure

-

Verify the suitability of equipment designs before they are built

-

Optimise capital investment

-

Minimise risk of under-performance or down-time

-

Reducing project cycle time

Interested?

Do you need understanding of your complex multi-phase flows or a failure root cause analysis?