R&D

Be it scaled testing of a field separator for an oil company, product development and qualification for a services company or in-house Research & Development for our own purposes, our independent test facilities are an essential part of the Kranji services offering.

Laboratory Building

Located in Arnhem in the East of the Netherlands, our test facilities host a range of carefully selected apparatus which can be flexibly configured to conduct experimental test and analysis of horizontal separators, vertical scrubbers, and produced water equipment. Controlled flow conditions can be set for a range of 2-phase (gas/liquid), 3-phase (gas/oil/water) and 4-phase (gas/oil/water/particulate) flow systems. Whilst the main applications are multi-phase flow and separation related, physical modelling can encompass heat transfer and other process concerns.

Technology mapping

At customer’s requirement we may test separation equipment as a complete system, or alternatively focus on individual components such as (cyclonic) inlet devices; distribution baffles; plate pack coalescers, agglomerators, mesh pad demisters, vane packs demisters, demisting cyclones, hydro-cyclones, de-sanding equipment and more. Where appropriate, parts of our test infrastructure are fabricated in transparent polycarbonate, to allow direct observation of the flow characteristics. A comprehensive system of process instruments are monitored to log key performance parameters and operating conditions.

The tests can be performed with a range of fluids with different properties (density, viscosity, surface tension).

Measurements and analysis

For quantified performance evaluation the following measurements are routinely undertaken:

-

Pressure drop

-

Liquid in gas carry-over

-

Gas in liquid carry-under

-

Water in oil

-

Oil in water

-

Droplet & bubble sizing (image-based analysis)

In addition our long experience provides vital qualitative insight for product development or performance validation from:

-

Visual observations

-

Prediction analysis for extrapolation to field operating conditions

CFD and R&D

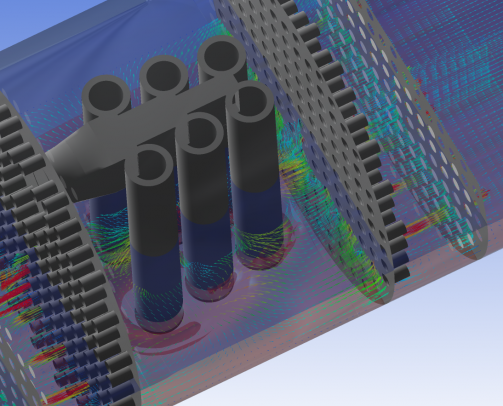

At Kranji solutions physical testing is often coupled with CFD modelling and theoretical analysis to provide deep insight into flow phenomena causing process bottlenecks and mal-performance. Our unique combination of skilled staff, specialist facilities and analytical experience make us the premier choice for process operators and service companies with challenging requirements in phase separation and associated multi-phase flow processes.

Interested?

Are you looking for specialist development and validation for phase separation and related processes?